Laser Cutting, Bending, and Tapping of 5052 Aluminum Parts

Jun 30, 2025

10 Ansichten

Chatten

Working with 5052 aluminum often seems simple on paper, but once you step into real production—especially when laser cutting, bending, and tapping are all involved in one workflow—you quickly realize the material behaves differently than standard 6061.This guide summarizes first-hand shop experience , verified machining data , and common failure cases to help engineers, buyers, and technicians get reliable and repeatable results. What Makes 5052 Aluminum Special for

-

Bearbeitungsteile kundenspezifische Präzision CNC, die Truning-Metallservice-Herstellung mahlen

View Detail -

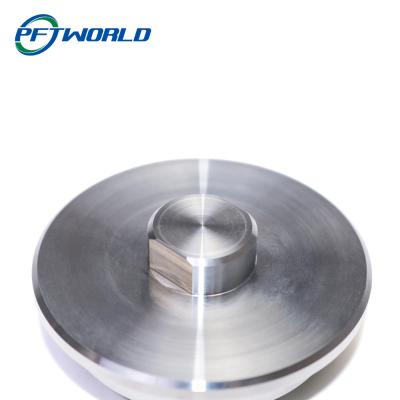

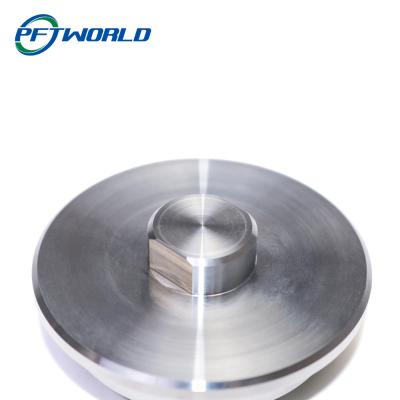

PFT ODM-Soemaluminiumdrehteile, Polier-Bearbeitungsprototyp-Service CNC

View Detail -

Stahlschieber linear-Verstellgerät CNC, lineare Bewegungs-Schiene des Blech-ISO9001

View Detail -

Führer-Schieber-Spiegel-Polieroberfläche des Edelstahl-HGR15 linearer

View Detail -

CNC-Dreh- und Fräsen von Teilen aus Edelstahl

View Detail -

Präzision kleine Drehentoleranz 0.01-0.05mm CNC der Präzisionsteil-ISO9001

View Detail -

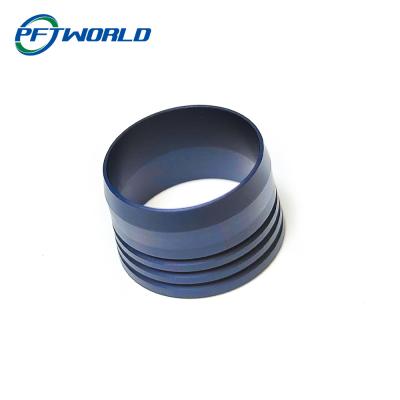

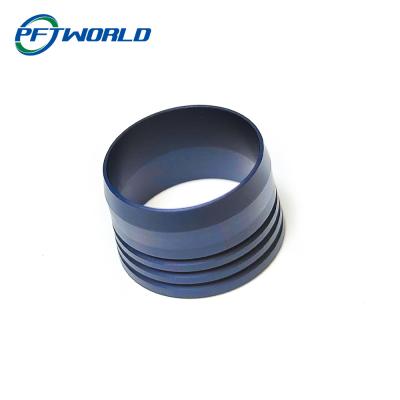

Drehenteil-Plastik Delrin POM Machining Edelstahl CNC

View Detail